The majority of people not in the crane industry assume that buying a bridge crane is just buying a bridge crane or buying a monorail crane is just buying a monorail crane but that is just not the case. In fact, many manufacturers of crane systems fail to mention some issues that may arise during the installation or usage of their products. All these factors contribute to the cost of ownership and should be evaluated during your purchase. Items like tie-backs, which are used to attach a bridge crane to an existing structure in your facility are added cost to you during the installation and are not covered with the purchase of the unit. Other items like headers or cross-braces are required to stabilize the unit so that it does not shake nor move during operation even though the bridge crane system may indeed meet industry standards. The best solution for you the consumer is to educate yourself as much as possible during the decision-making process. Buying cheap is not always the right solution for someone looking to save money on purchasing a bridge crane.

Bridge Crane Buying Factors

Other factors also include coverage of the system. While comparing units, they may have the same footprint in coverage from one another; but there can be drastic differences. Length of the end trucks, used to support the bridge along the runway, which control the coverage or square footage achieved with the bridge or hoist trolley. More often than not, manufacturers that build articulating crane systems tend to have shorter-end trucks and achieve greater coverage within the same constraints. Rigid systems that do not allow the bridge to articulate down the track need to have really long and trucks to allow the bridge to track to straighten. These longer-end trucks not only decrease the coverage of the hoist trolley; but also have a high maintenance factor due to their guide rollers always being utilized during use. The fact is, all bridge cranes articulate; it is just to what extent. When the bridge is constrained to being rigid it makes operation more difficult for the user since the unit is trying to fight its own inherent motion and relies upon bearings to help it to track straight. These same rollers tend to wear out easily and this drives up the cost of ownership.

Conclusion

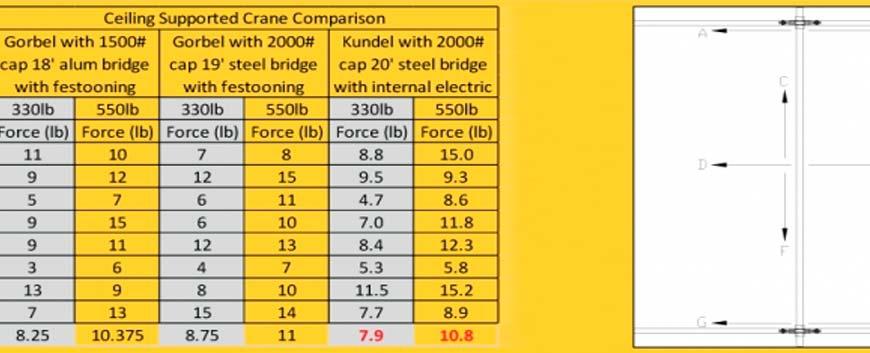

So next time you are looking to purchase a cheap or inexpensive bridge crane system dive into the details, you will be happy you did. Reference above chart for typical push/pull factor generated by a David Henkel of Amsted Rail that chose to purchase Kundel after reviewing all the facts.