Titan Series Trench Boxes and Steel Trench Shields

Trench Boxes | Mainline Sewer & Water Installation and Specialty Trench Shields

Trusted by Worldwide Companies

LONG LASTING

DURABLE

LIGHT WEIGHT

MACHINE MATCHED

SMART CONNECT

EASY DRAGGING

TRENCH BOX BASICS AND HOW THEY WORK

What is a trench box?

A trench box is typically comprised of two fabricated steel or aluminum panels, commonly referred to as side walls, separated by a series of pipe at each end of the assembly. The trench box is designed to save lives in the trenches by providing a safe working area when performing pipe repairs or laying sewer and waterline pipe.

When is a Trench Box Required?

OSHA requires excavation 5’ or deeper in depth to have shoring or shielding to protect workers in the trench and, at times, stabilize the surrounding soil to avoid undermining nearby structures.

Are job built Trench Boxes Allowed?

The simple answer is no. Every trench box on the jobsite needs to have engineering calculations behind it and tabulated data to go along with it that will need to be readily available for any OSHA inspection.

1. How do you use a Trench Box

The usage of a trench box is a relatively simple process. To start, you will assemble your trench box sidewalls using the spreader pipes and locking pins you purchased with your product, you will find more detail on assembly in your Kundel Owner’s Manual. Once your trench box is assembled you will place it into your excavation prior to any workers being allowed to enter. A common process will be digging down to your desired grade, inserting your trench box, adding and bring base materials to required grade, installing your utility to required grade, excavating ahead of the trench box and dragging ahead to repeat the process.

2. Can Trench Boxes be stacked

Absolutely. Trench boxes can be stacked in many different configurations to achieve the proper depth and coverage necessary for each project. Many trench boxes are designed to stack and have the built-in features to handle this type of application.

3. What size Trench Box is right for me

There are many sizes and wall thicknesses of trench boxes available depending on your job conditions, depth requirements, utility working with, and excavator size. Your trench box specialist at Kundel can help you determine the best product to match your job needs. As stated above, OSHA requires some form of shielding or shoring with any excavation of 5’ or greater in depth. The type of trench protection product you choose will also require you to determine if your needs are to simply shield (trench shield) or to stabilize the surrounding soil (trench shoring). Trench shielding is the most common type, and this is done buy excavating and inserting your trench box(s) while backfilling accordingly to prevent lateral shield movement. With Trench shoring you are installing in a manner that stabilizes the surrounding soil, this application is commonly done by driving down your shoring product while excavating inside.

TRENCH SAFETY EQUIPMENT SIZED FOR YOUR JOBSITE

SAFETY FEATURE | Internal Stacking

Maintain a safe jobsite using our internal stacking points. This feature keeps your crew inside the trench box protected zone while safely stacking and attaching additonal boxes.

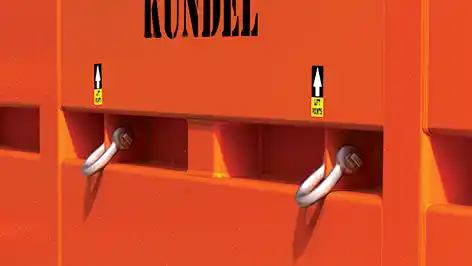

SAFETY FEATURE | Internal Lifting

Keep your crews safe during rigging operations while moving your trench box by utilizing our receessed pocket lifting points. These points are flush mount and keep a clean work zone.

18″ Easy Glide Knife Edge

Quickly and easily cut through the soil as you drag your trench box ahead utilizing our Titan Series 18″ high tappered knife edge. Standard on every Titan Seres Trench Box.

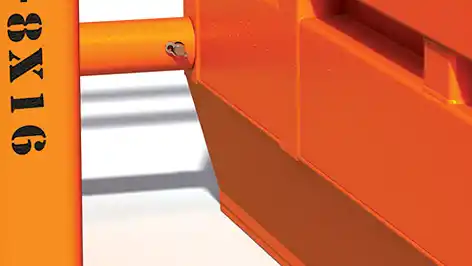

Heavy-Duty All Steel Cast Socket

Industry leading and first is our thru-wall all steel heavy-futy cast sockets. These socket have 10X the material at the point of tear-out decreasing your cost of ownership.