Cold mix is being phased out—not because it’s inconvenient, but because it’s unsafe.

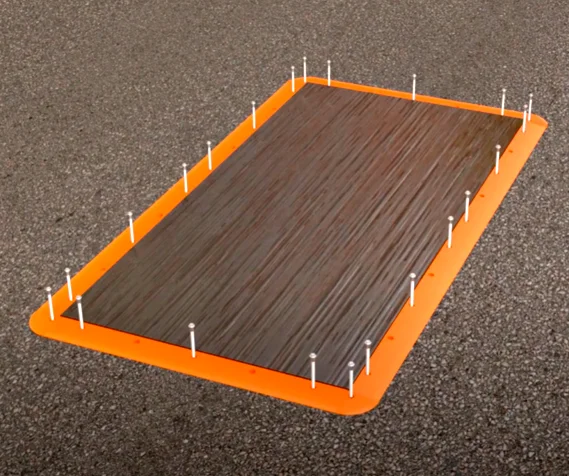

Cities and counties across the U.S. are rewriting trench safety protocols, moving away from outdated, high-liability materials in favor of more secure, long-term solutions. One of the most widely adopted? Plate Locks—a mechanical road plate securing system built to meet today’s safety demands.

Watch Plate Locks Installation video.

The Hidden Costs You’re Already Paying For

What looks like a cheap solution often costs more in the long run.

With every job, cold mix racks up:

- Excess labor hours

- Repeated applications

- Site cleanup

- Hazardous material disposal

- Emergency rework

- And increasing exposure to public complaints and claims

Meanwhile, your team is still on the hook for compliance, maintenance, and inspection.

A Shift in Standards: Cities Are Demanding Safer Alternatives

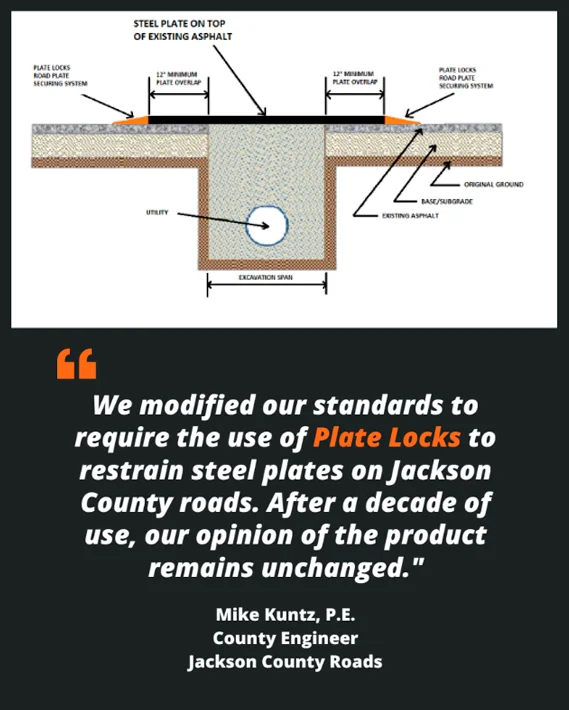

Municipal engineers and DOT leaders are making the shift—fast. Several counties, like Jackson County Roads, now mandate mechanical plate securing systems. Why? Because they work.

What Makes Plate Locks a Smarter Standard

Plate Locks aren’t just safer—they’re smarter:

- Visually distinct (safety orange) to alert drivers and pedestrians

- Mechanically fastened, so they don’t shift under pressure

- Reusable and recyclable—no waste, no disposal

- Quick to install and remove—no site shutdowns for inspections

- Compatible with multiple plate sizes, even on uneven roads

This is how modern trench safety should operate—without guesswork or constant rework.

Choose Safety, Compliance, and Cost Control Over Convenience

If your teams are still relying on cold mix, now is the time to get ahead of the shift.

We’ll walk you through how Plate Locks work, what kits you’ll need, and how cities are building new standards around them.