Your crane still lifts — but is it safe? As we start 2026, it’s the perfect time to evaluate your equipment, protect your crew, and make smart decisions that improve both safety and productivity. Modernization and retrofits aren’t just upgrades — they’re commitments to doing the work right.

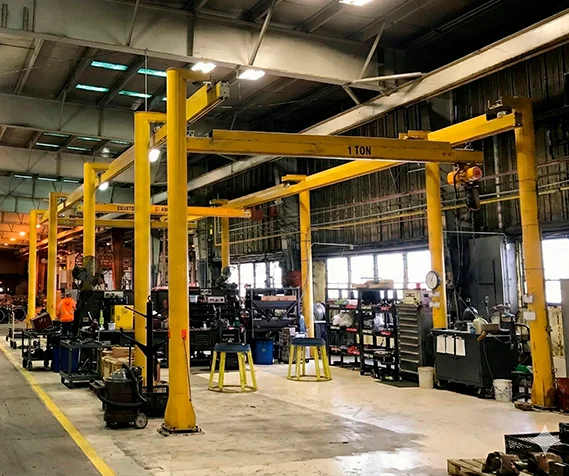

Whether it’s an overhead bridge crane or a gantry crane, the right system can dramatically reduce risk, improve workflow, and extend service life. Here are five ways to ensure your crane operates safely and efficiently this year.

1. Inspect, Maintain, and Modernize Critical Components

Even the most reliable crane can hide wear and tear that compromises safety. Start with a thorough inspection of mechanical, structural, and electrical systems, and don’t overlook control systems, brakes, or hoists.

Modernization might include:

- Upgrading load-moment indicators (LMI)

- Installing updated emergency stop systems

- Adding automation features or remote monitoring

Small updates now can prevent incidents later and extend the life of your equipment.

👉 Learn more about KUNDEL Overhead Bridge Cranes

2. Evaluate Whether Your Crane Matches Your Jobsite Needs

Ask the hard questions:

- Are the lifting capacities sufficient for current operations?

- Does the crane move materials efficiently across your workflow?

- Does your gantry crane fit the open space or outdoor demands?

Choosing equipment suited to your loads and workspace ensures crews don’t improvise — a major source of risk on busy sites.

👉 Check out KUNDEL Gantry Cranes

3. Train Your Crew and Reinforce Safe Practices

Safety technology only works if your team knows how to use it. Regular training and refresher courses should cover:

- Proper rigging and load handling

- Emergency procedures

- Operating limits of both overhead and gantry cranes

A knowledgeable crew is your first line of defense, even before equipment fails.

4. Make Safety Part of Daily Planning

Waiting until lifting starts to consider safety is too late. Make it part of your pre-lift checklist:

- Inspect the crane and site conditions daily

- Confirm clear paths and load stability

- Verify weight, rigging, and environmental factors

When safety is integrated into the workflow, it becomes routine, not optional.

5. Stay Ahead with Modernization and Retrofits

A crane that lifts isn’t automatically a safe crane. Modernization can:

- Reduce downtime and maintenance costs

- Improve precision and repeatability

- Protect crews from preventable hazards

The KUNDEL Titan Series cranes are designed with real-world conditions in mind — combining durability, reliability, and advanced safety features.

Safety isn’t something to compromise when production pressures rise. Make this your standard for 2026: if it doesn’t lift safely, it doesn’t lift. No excuses.

Start the Year with Confidence

Improving crane safety and performance doesn’t have to be overwhelming. By inspecting equipment, matching cranes to your needs, training your crew, integrating safety into daily planning, and investing in modernization, you can reduce risk, protect workers, and boost productivity.

Explore KUNDEL Crane Solutions: