Why most cranes underperform in tight spaces, and what smarter design really looks like.

A crane system can check every box on paper—and still let you down in practice.

It happens all the time: a system is installed, meets the technical spec, passes inspection…and within a few months, operators are double-handling loads, festoon cables are getting caught up in foot traffic, and the bridge doesn’t travel straight.

What looked good in a drawing just isn’t holding up on the floor.

The reason? We can name quite a few.

Common Failures That Eventually Cost You

In low-headroom or tight-floor environments (which is more common than not), standard cranes tend to fall short in five predictable ways:

- Lost hook height makes it impossible to lift in one clean move

- Heavy bridges wear down crews and slow down cycles

- Festoon cables clutter work zones and create snag points

- Bridge drift from poor leveling leads to uneven wear

- Building-reliant installs limit flexibility when layouts change

The downside? Chronic inefficiencies, frustrated crews, and increased maintenance over time. Is KTRAC Right for you? Find out here.

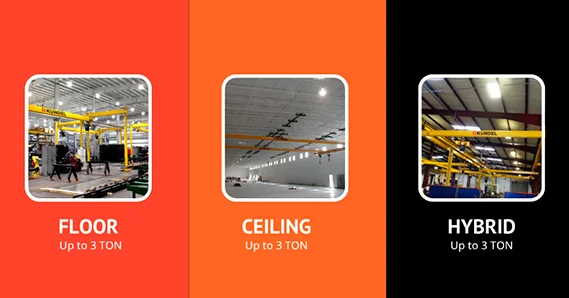

Mounting Options

What “Built to Last” Actually Looks Like

A crane system built for long-term performance—especially in tight or complex spaces—looks different from the standard catalog model.

You should be looking for:

- Raised bridge ends to maximize lift in low-clearance environments

- Lightweight, roll-formed bridges for smoother, faster operator movement

- Internal power delivery to eliminate festoon clutter

- Leveling hardware to prevent tracking issues and extend system life

- Modular, free-standing frames that install clean and adapt as you grow

These design choices aren’t about bells and whistles. They’re about reducing friction where it matters most: in daily operation, year after year, after year!

The Smarter, KUNDEL way

You don’t need more crane—you need the right one.

One that gives you the hook height you’re missing.

One that moves clean. Tracks straight. Stays out of your way.

One that works like it’s supposed to—without workarounds or extra steps.

That’s what KTRAC® was built to do.

Low headroom. Tight layouts. Real crews doing real work. The features that solve those problems? They’re not upgrades. They’re standard.

Because performance on install day is great.

But performance five years in? That’s what we build for.

👉 Talk to a Crane Expert → Contact Our Team

Let’s walk through your layout and help you figure out whether your current system is built to last—or just built to spec.