Most trench systems are sold as “protection.”

But in soil mechanics, there’s a critical difference between protection after movement and prevention before movement.

Understanding active vs passive shoring can change your entire risk profile.

Passive Shoring: Engages After Soil Moves

Passive systems, like trench boxes, resist soil after the trench wall shifts.

- Soil moves

- The box is loaded

- The structure resists collapse

They protect workers inside the box, but they require movement to activate. That initial displacement can contribute to surface settlement and risk near roads, sidewalks, or adjacent structures.

Active Shoring: Stops Movement Before It Starts

Active shoring — hydraulic trench shoring — applies outward pressure immediately.

Hydraulic cylinders press against trench walls, compressing the soil before it shifts. In cohesive soils (Type A and B), this creates a stabilizing “arching” effect that helps hold the trench in place.

Instead of reacting to movement, active systems work to prevent it.

That’s the core difference in hydraulic trench shoring mechanics.

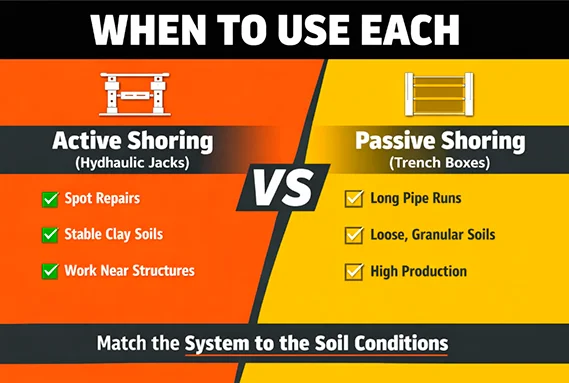

When to Use Each

Active Shoring (Hydraulic Jacks)

✔ Spot repairs

✔ Stable clay soils

✔ Work near existing structures

Passive Shoring (Trench Boxes)

✔ Long pipe runs

✔ Loose, granular soils

✔ High-production environments

Both have value. The key is matching the system to soil behavior.

The Critical Factor: Maintaining Pressure

For active shoring to work, pressure must be maintained.

If hydraulic seals leak, outward force drops.

If outward force drops, compression disappears.

If compression disappears, active shoring becomes passive…without warning.

This is where system design matters.

The KUNDEL Trenshore System features Positive Triple Seal Cylinders, engineered to maintain consistent pressure in the field. Pressure stability isn’t a feature, it’s the foundation of active shoring performance.

Prevent movement before it happens with the active pressure of the Kundel Trenshore System.