The Quiet Cost You’re Not Measuring

In most facilities, ergonomics gets treated like a compliance checkbox: “Are we OSHA‑safe? Did we buy the anti‑fatigue mats?” It’s buried under HR initiatives and safety posters.

But here’s the uncomfortable truth: ignoring ergonomics is bleeding throughput and profits. Every strained shoulder, every micro‑pause to readjust grip, every time an operator hesitates before moving a 200‑kg part — it adds up. Across shifts, across lines, across the year.

“Incorporating The Binar Arms Into Our Production Has REVOLUTIONIZED Our Process; Making The Movement Of Our Windows Effortless.”

– Matt Dagget – JELD-WEN

Traditional Arms: Safe Enough Isn’t Good Enough

Conventional lifting arms do one thing: offset weight. But they do it rigidly. They fight the operator’s natural motion instead of flowing with it. This leads to:

- Slower cycle times — operators compensate for jerky movements.

- Higher fatigue — “weightless” doesn’t feel weightless when you fight the arm itself.

- Turnover risk — workers burn out faster in roles that strain their bodies every shift.

The result? A hidden drag on profit that rarely shows up on a spreadsheet but is felt on the floor every single day.

The New Model: Human‑Centric Lifting

Articulated, servo‑controlled arms are changing the equation:

- Auto‑balanced movement: Whether it’s 50 kg or 300 kg, the load feels the same.

- 360° ergonomic reach: Arms pivot like a human shoulder and elbow, eliminating awkward postures.

- Natural operator control: No buttons, no toggles — just guide and go.

- Low‑maintenance design: Integrated mechanical, electric, and pneumatic swivels reduce downtime.

Why It Matters Right Now

- Retention is critical: Skilled operators are harder to replace than ever; a safer, easier job is a recruiting tool.

- Lean demands speed: Human‑centric arms cut wasted motion and make mixed‑model lines viable.

- Compliance is baseline: Competitive advantage is about exceeding “safe enough” and achieving effortless.

Where KUNDEL’s QLA Arms Fit

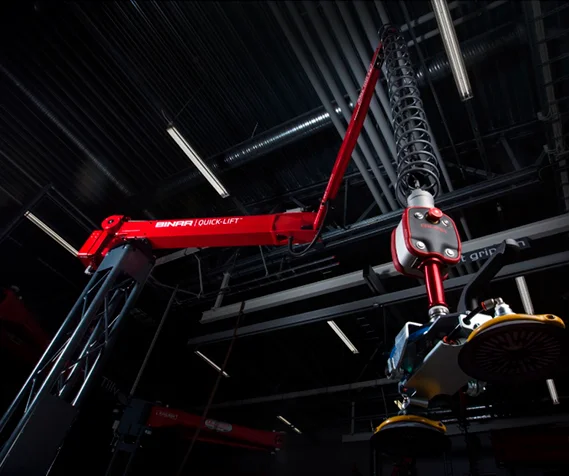

This shift isn’t theoretical — it’s already here. KUNDEL’S Quick‑Lift Arm (QLA) series applies the same human‑centric philosophy across four capacities: 50 kg, 100 kg, 200 kg, and 300 kg. Each offers multiple reach options (3m, 4m, 5m) and a universal 2.7m vertical stroke to fit most assembly and handling environments.

It’s the same intelligent lift technology used in rail systems — re‑engineered in arm form for flexible, pillar‑mounted installation where overhead rails aren’t feasible.

If your facility is still using rigid arms or hoists, ask:

- How many seconds are we losing per lift?

- How many operators quit because the work feels harder than it should?

- How long until that hidden cost becomes impossible to ignore?

Learn more about QLA arms →

Watch Quick-Lift Installation Video