EFFORTLESS WEIGHT CONTROL WITH THE TOOL BALANCER

ERGONOMIC EFFICIENCY

STURDY CONSTRUCTION

WIDE-RANGING APPLICATIONS

DEDICATED SAFETY MEASURES

ATEX CERTIFICATION

ESD-PROTECTION APPLICATIONS

OVER 7 MILLION TOOLS IN SERVICE

Tool Retractors

General Purpose Balancers & Retractors

Stainless, Aluminum or Nylon Body

Auxiliary Safety Suspension

Food Industry Balancers

Meets All Food Industry Standards

Stainless Materials on All External Parts

Stainless Steel Rope

1. Improved Workplace Safety

The tool balancer is designed with fall protection elements, effectively cutting down the risk of tool-related accidents. By applying consistent tension, it supports heavy devices and helps operators avoid sudden strain or drops.

This commitment to safety results in a more secure environment where tasks can be completed promptly and efficiently.

2. Operator Comfort and Health

With the tool balancer’s spring-based mechanism, tools feel nearly weightless. This feature greatly diminishes the muscle fatigue and repetitive stress injuries that often arise from manual lifting.

By aligning with ergonomic best practices, the balancer reduces physical strain, allowing team members to work longer and more comfortably.

3. Enhanced Productivity and Quality

Minimizing manual effort frees workers to concentrate on precision, speed, and overall job quality. Because the tool balancer keeps tools stable at any height, operators can quickly maneuver devices without wrestling with additional weight.

This consistent balance promotes smoother workflow and increases throughput, all while maintaining accuracy.

DISCOVER THE VERSATILITY OF THE TOOL BALANCER

Many Applications in One Device

Power tools like drills, staplers, and torque arms, Pneumatic rivet guns and hydraulic crimpers, Welding stations using weld guns or transguns, Food processing tools, including bone cutters and skin removers, Vacuum hoses and cable management lines in washdown areas, Pallet wrap machines, marking devices, or strapping tools, Sliding windows, doors, or mobile barriers in automated systems, etc.

TOOL BALANCER FAQS

How do I select the right load capacity and cable stroke?

Start by calculating the total weight of the tool or any attachments. Aim for a load rating that slightly exceeds that sum to ensure balanced lifting and smoother tension. Next, confirm the vertical distance the operator requires to move the device.

A suitable cable stroke will accommodate both high and low positions, preventing any abrupt stops or slack. Matching capacity and stroke carefully ensures reliable, fatigue-free operations.

How can I ensure the tool balancer remains in prime condition over time?

Regular maintenance is crucial to guaranteeing optimal performance. Begin with routine cable inspections: look for fraying, kinks, or signs of wear, and replace any compromised components immediately.

Keep an eye on the balancer’s internal spring mechanism by listening for unusual sounds or feeling sudden tension changes, as these can indicate potential problems. Lubricating moving parts with manufacturer-approved products helps sustain smooth operation.

Additionally, consider periodic checks of attachment points to confirm they remain secure. By following recommended service intervals and swiftly addressing any minor issues, you can prolong the tool balancer’s lifespan, prevent downtime, and maintain safe conditions for everyone on the job.

What distinguishes a spring balancer from other lifting devices?

A spring balancer maintains constant tension through a coiled mechanism, making tools feel almost weightless. Traditional hoists or pulleys can create slack or abrupt drops, which raises the risk of damage or operator strain.

In contrast, the tool balancer delivers smooth, controlled movement and incorporates extra safety features like secondary locks. Its minimal bounce ensures better accuracy for repetitive tasks. This design not only boosts efficiency but also protects the workforce and expensive equipment.

Are specialized attachments or brackets available for unique tools?

Yes. Many work environments involve distinctive equipment or accessories that require specific mounting solutions. The tool balancer can often be paired with custom hooks, clamps, or brackets designed to hold specialized devices securely. For instance, a custom bracket might accommodate an oddly shaped handpiece or a sensitive measuring instrument.

By consulting with your distributor or the balancer’s technical team, you can determine if a ready-made option exists or if a tailored solution is needed. This level of customization ensures your tool remains stable and properly supported, helping operators maintain accuracy and consistent tension

EXPLANATORY VIDEOS

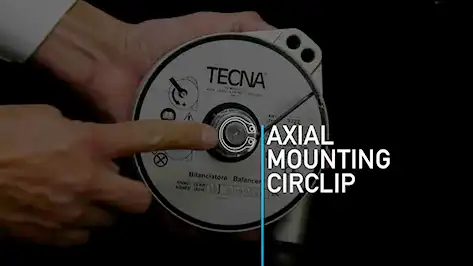

Axial Mounting Circlip

An axial mounting circlip has been added to the front part of the balancers, ensuring greater resistance to impact.

New Adjustment Bushing

To protect the balancer from potential damages the adjustment bushing has been entirely redesigned.

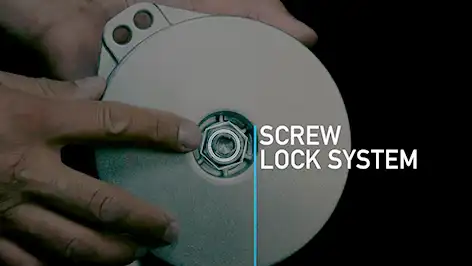

Screw Lock System

A simple, yet effective screw lock system that guarantees a high level of reliability of the balancers.

Safety Cap

The cap of the circlip and central pin is able to absorb impact and provide information on the state of the balancer.

QUOTE REQUEST

A knowledgeable Kundel specialist will help you

To request a quote, please complete the form below. We will respond within one business day. If you have a more urgent request, please call us at 330.259.9009 for immediate assistance.