Because no one wants to fight their tools all day.

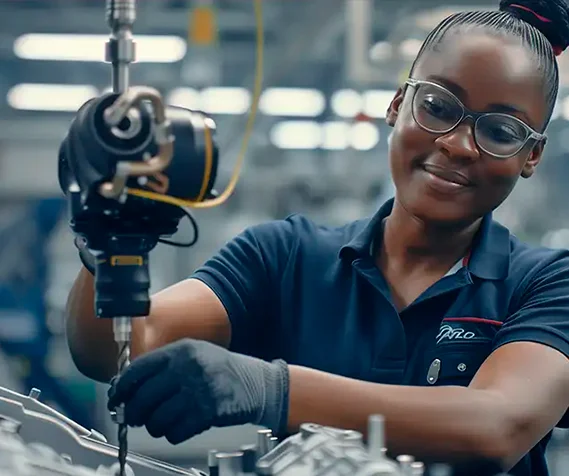

The Challenge: Heavy Tools, Repeated Lifts

Air hammers, impact guns, torque wrenches—some weigh 50 lbs or more and get lifted 100+ times a shift. That adds up fast: sore shoulders, slowed productivity, and real safety risks when fatigue sets in.

Retractors: Reliable Workhorses

Retractor balancers are built for repetitive, straight-forward lifts. They keep tools close, minimize clutter, and handle high-cycle use without complaint. For many shops, they’re the go-to because they’re simple, dependable, and cost-effective.

Zero Gravity: Tools That Float

But when precision, ergonomics, or long shifts come into play, zero-gravity balancers change the game. Instead of pulling against spring tension, the load balances to zero weight. Your tool hovers where you leave it—ready when you need it, out of the way when you don’t.

That’s not just convenience. It’s control. It’s fewer mistakes when accuracy matters most. It’s less fatigue by the end of the day.

Why Crews Trust the TECNA 9313

Not every zero-gravity balancer is created equal. The TECNA 9313 is built for environments where failure isn’t an option:

- Stainless steel rope — corrosion-proof in humid, dirty, or salty conditions

- Cast aluminum body — light enough to handle, tough enough to survive impacts

- Auxiliary safety suspension — a critical backup that keeps tools secure

- Adjustable load capacity (2–3 kg) — dial in the exact balance you need

- Four-lobe adjustment knob — 30% more accuracy, faster setup

- QR code support — instant access to manuals and install videos from your phone

Watch the side-by-side demo: TECNA Zero-Gravity vs. Retractor Balancers

Proof in the Field

Dropped tools are one of OSHA’s top causes of struck-by injuries. Reliable balancers reduce that risk—and crews report less fatigue, smoother handling, and fewer stoppages when they switch.

That’s why the TECNA 9313 has become a best-seller: it’s not just a tool balancer. It’s a safeguard for uptime, precision, and the people running the job.