Why This Decision Comes Up in Material Handling

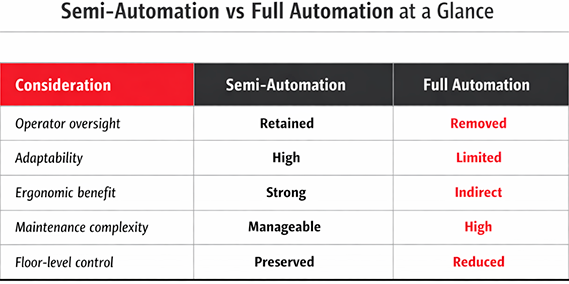

In many facilities, automation becomes part of the conversation during growth, safety reviews, or when teams are asked to move heavier loads more efficiently without increasing risk. In material handling environments, the question is rarely whether automation is needed, but what level makes sense.

For lifting and positioning tasks, this decision directly impacts operator safety, ergonomics, and long-term reliability.

Where Fully Automated Handling Requires the Right Fit

Fully automated handling systems perform best when loads, paths, and operating conditions are well defined and consistent. In many facilities, however, variables can change over time.

When lifting and positioning are fully automated:

- Maintenance planning becomes more specialized

- Small deviations may require system-level adjustments

- Recovery relies on automated logic rather than on-the-floor judgment

- Floor-level flexibility depends on how the system is configured

In safety-critical environments, fully automated solutions must be carefully designed to ensure they align with real operating conditions and long-term support requirements.

How Semi-Automation and Ergonomic Jib Arms Change the Equation

Semi-automation takes a different approach by assisting the operator rather than replacing them.

Using solutions like ergonomic jib arms and assisted lifting systems:

- Loads are controlled, not forced

- Operators maintain visibility and control

- Physical strain is reduced without removing responsibility

- Precision improves without sacrificing adaptability

This balance is especially valuable where lifting tasks vary and accountability matters.

A Practical Approach to Assisted Lifting

At KUNDEL, semi-automation is a design philosophy. Solutions like BINAR are developed as part of KUNDEL’s broader lineup of custom lifting devices, including ergonomic jib arms that support safe, repeatable motion while keeping operators engaged in the task.

Learn more about:

Choosing the right level of automation isn’t about eliminating people from the process. It’s about designing systems that support how work actually happens.

The strongest lifting solutions don’t replace workers.

They make the work safer, smarter, and more sustainable.