In manufacturing, downtime is the enemy.

When materials aren’t moving, production slows, schedules slip, and costs rise. The best way to protect both your people and your output? Keep your lifting equipment in peak condition—always ready, always safe.

Two proven technologies dominate the material handling space: vacuum lifts and magnet grippers. Each has strengths, limits, and ideal applications—but the bigger picture is making sure whichever you choose is reliable, maintained, and matched to your process.

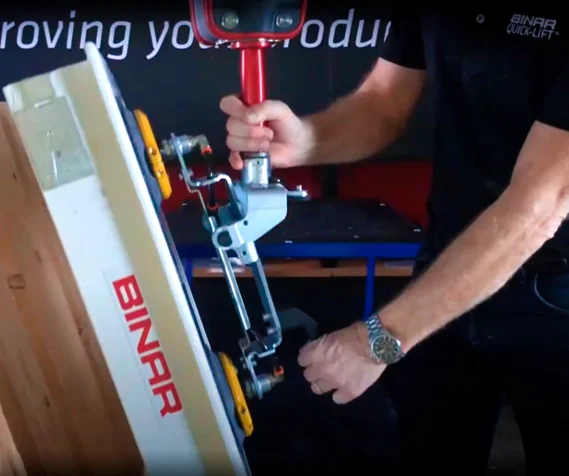

When to Use Magnet Grippers

Magnetic lifting systems are a go-to for ferrous materials—steel plates, fabricated assemblies, structural components. They offer:

- Fast engagement with metal surfaces

- No power loss during a lift (with permanent magnet options)

- Reliable performance on rough or dirty surfaces

Limitations? They won’t work with non-metallic materials, and certain coatings or gaps can reduce holding force.

📺 Watch magnet grippers in action here

When to Use Vacuum Lift Assists

Vacuum systems excel when surface finish matters or materials aren’t magnetic—smooth metal sheets, sealed panels, glass-reinforced components, and more. Benefits include:

- Non-marking lift for finished surfaces

- Adaptable pad configurations for different shapes and sizes

- Easy integration with cranes or gantry systems

One requirement: a secure seal. If your surfaces are porous, heavily textured, or warped, the right pads and pump system are essential.

📺 Check out vacuum lift assist systems in real-world use

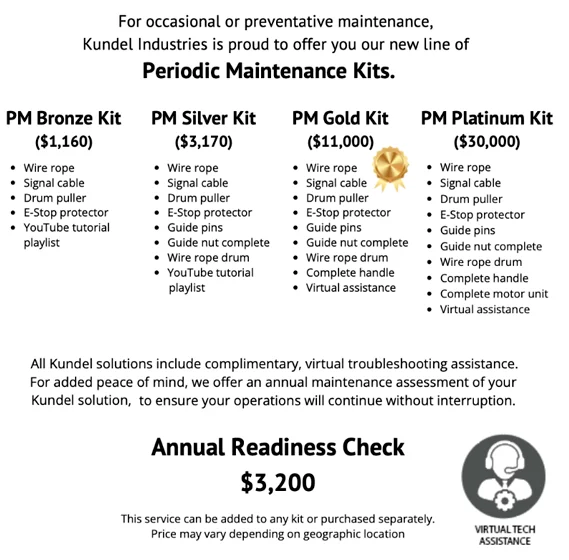

Why Maintenance Matters More Than the Method

The fastest way to lose productivity is equipment failure in the middle of a shift. Both vacuum and magnet lifts need routine inspections, part replacements, and seal or pad checks. That’s why Periodic Maintenance Kits are a game-changer—keeping essential parts on hand so crews can perform service without delays.

👉 Updated maintenance kits are now available.

Bottom Line: Choose for Application, Not Just Budget

Vacuum and magnet lift systems are both strong choices—but the best tool depends on your material, environment, and jobsite needs. If you’re planning a new lift process, upgrading older systems, or just trying to cut back on rigging time, understanding your options is the first step.

Whether you source from KUNDEL or another supplier, make sure your vendor:

- Offers standardized and proven solutions

- Supports install and training

- Provides a clear maintenance path post-purchase

Because in this industry, you don’t just buy equipment—you buy uptime.

Want help choosing the right lift system?

Need install supervision or standard kits that keep your system running?

👷♂️ Contact a specialist who understands heavy-duty jobs.

📞 1.877.586.3353