LEADING JOBSITE SAFETY SOLUTIONS

Empower Teams, Protect The Public: Advanced Jobsite Safety Solutions For Faster, Simpler Jobsite Security

LIGHTWEIGHT BUILD

WIND-RESISTANT

ANTI-SLIP GRIP

QUICK INSTALLATION

MODULAR DESIGN

SUSTAINABLE MATERIALS

EXPLORE FOUR ESSENTIAL JOBSITE SAFETY SOLUTIONS

Jobsite Barriers

Tamper-resistant panels

Heavy-duty base ensures stability

Ideal for high-traffic areas

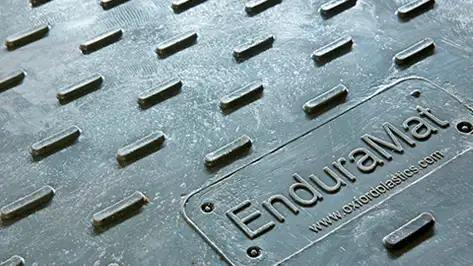

Jobsite Ground Protection

All-weather anti-slip surface for Site Safety

Supports vehicles and pedestrians

Lightweight for quick relocation

Tools and Acessories

Essential aids for enhanced Jobsite Safety

Streamline installation and maintenance

Extend product life with spare parts

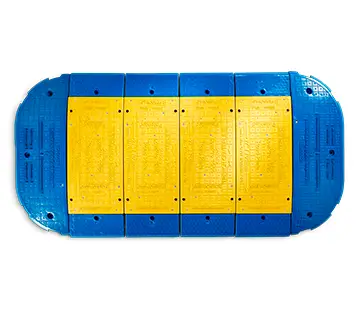

Jobsite Plastic Road Plate

Handles up to 97,000 lbs

Noise-dampening edges provide comfort

Installs fast without heavy machinery

1. Unmatched Durability and Stability

Each solution in this range is built with robust materials that stand up to demanding work conditions. From heavy loads on road plates to strong, tamper-resistant barriers, these products withstand repeated use in even the busiest environments.

The integrated rubberized or textured edges boost traction and help prevent slips, ensuring that Jobsite Safety remains a priority at every turn. With minimal need for extra reinforcement, teams can focus on tasks rather than worry about whether the equipment can handle the job.

2. Simplified Installation and Reduced Downtime

Quick installation is a top priority in busy work areas, and these products deliver. Trench covers can be placed without bolting, while barrier systems feature a minimal number of components for speedy assembly. The lightweight design of temporary walkway mats and plastic road plates eliminates the need for heavy machinery, helping crews accomplish more in less time.

By streamlining setup and teardown, these Jobsite Safety solutions let projects progress smoothly, keeping lanes open and hazards under control.

3. Eco-Friendly and Cost-Effective

Sustainability drives the design of these modern solutions. Materials are often recycled or recyclable, reducing waste and supporting responsible resource use. Moreover, investing in durable Site Safety equipment means fewer replacements over time, shrinking both costs and environmental impact.

By cutting down on the need for powered installation tools, teams also lower fuel usage and emissions. This green approach doesn’t sacrifice performance; instead, it delivers a more efficient, earth-conscious way to ensure maximum protection at every jobsite.

JOBSITE BARRIERS

StrongFence and StrongWall Barriers offer a high-visibility solution for separating people, equipment, and traffic in a wide range of environments. Their sturdy, interlocking base system resists wind and prevents unintended dismantling, while tall fence panels deter climbing and keep work zones secure.

These barriers are made entirely from non-conductive materials, making them suitable for sites with electrical risks. By deploying this barrier system, you uphold high Jobsite Safety standards, reduce pedestrian hazards, and streamline jobsite organization.

JOBSITE GROUND PROTECTION

For projects requiring safer walkways or temporary ground cover, these mats shine with their adaptable grip and reliable performance. They can support both pedestrians and heavy vehicles, maintaining a steady surface even on muddy, uneven, or wet terrain.

Lightweight connectors allow quick installation, creating a continuous path that helps prevent slip-and-fall incidents. Their dual-sided traction ensures efficiency, whether you’re forming a pedestrian route or a makeshift driveway. In doing so, you reinforce Jobsite Safety while minimizing ground damage.

JOBSITE TRENCH COVER

This modular trench cover setup is an excellent alternative to traditional steel plates or plywood boards. Engineered to bear weight without bolting in most cases, the covers feature anti-slip surfaces to guide pedestrians and reduce accidents.

Flexible infill strips let you expand coverage for any length of excavation. By removing the need for cold patch ramps and heavy equipment, this system boosts Jobsite Safety and keeps sidewalks or paths accessible, minimizing disruptions around your work zone.

JOBSITE PLASTIC ROAD PLATE

These plastic road plates transform how you manage traffic over trenches up to 28 inches wide. Each plate is lighter than steel yet strong enough for vehicles up to 97,000 pounds. Smooth, rubber-like edges reduce noise and provide a comfortable driving and walking surface.

The modular structure allows quick placement by hand, lowering installation costs and emissions. From busy urban roads to industrial complexes, this road plate system advances Jobsite Safety while simplifying transportation and storage requirements.

The image shows one of our experts holding the Plastic Road Plate, revealing its underside with rebar reinforcement clearly visible.

FREQUENTLY ASKED QUESTIONS ON JOBSITE SAFETY SOLUTIONS

How do these products ensure maximum safety in high-traffic zones?

These solutions blend durable construction with intuitive design to protect both workers and the public in busy areas. For instance, barriers feature a secure locking system that resists tampering, while trench covers offer slip-resistant surfaces to help prevent accidents. Their modular nature accommodates evolving jobsite needs.

By aligning with key regulations and centering on Jobsite Safety from the initial setup to final removal, these products minimize risk and maintain reliable performance over extended periods of use.

Are these Jobsite Safety solutions cost-effective in the long run?

Absolutely. While the upfront investment may differ from traditional steel plates or wood boards, the long-term savings can be significant. Lightweight construction reduces transport and lifting equipment expenses, and robust materials mean fewer replacements. Beyond financial advantages, fewer disruptions during installation or removal keep projects on schedule.

Additionally, Site Safety plays a pivotal role in mitigating liability concerns, ultimately providing a more secure, efficient, and budget-friendly approach that supports both productivity and public welfare.

Anti-Slip Surfaces

Textured patterns ensure pedestrians and vehicles remain secure, providing an anti-slip surface for Jobsite Safety

Recycled Materials

Eco-friendly design reduces waste and lowers environmental impact, contributing to sustainable jobsite practices

Easy Storage

Stackable panels and lightweight mats simplify storage and transport, minimizing hassles across diverse project sites

Reduced Noise

Rubberized edges strengthen Jobsite Safety by reducing noise, preventing loud clattering and improving on-road comfort